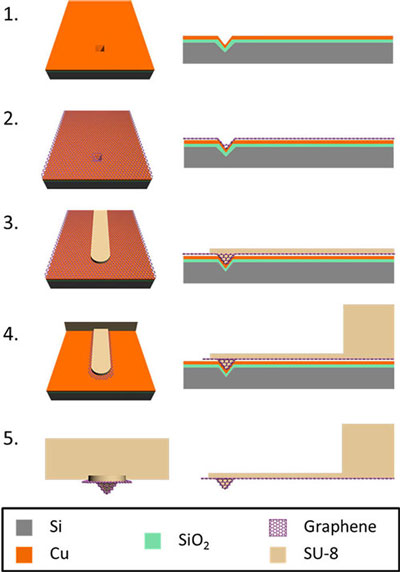

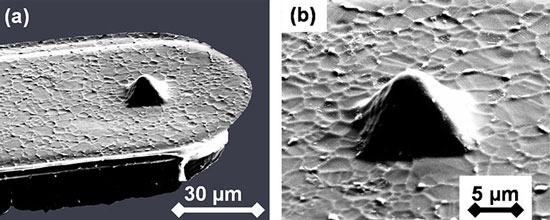

Most of the research efforts on developing synthesis methods for graphene has focused on flat substrates. Some groups have reported the formation of free-standing 3D graphene-based macroscopic structures (see for instance "Making graphene 'bread' - leavening technique results in freestanding graphene oxide films"). However, direct growth of graphene layers on prepatterned substrates has remained elusive.In previous work, researchers led by James K. Gimzewski at UCLA have already shown that graphene grows continuously over large areas on different copper terraces without the underlying substrate morphology affecting the atomic arrangement of the grown material ("Continuity of Graphene on Polycrystalline Copper"). In new work, just reported in ACS Nano ("Graphene MEMS: AFM Probe Performance Improvement"), the team has applied this technique to grow graphene in prepatterned copper-coated substrates, and they apply this protocol for the fabrication of MEMS devices, in particular, atomic force microscope (AFM) probes."Conformal deposition of graphene on prepatterned substrates opens a multitude of device fabrication possibilities," writes Gimzewski. "One of them is the addition of different layers to the graphene, mostly by deposition, using the prepatterned substrate as a mold. This can result in hybrid 3D structures covered with graphene."In this new work, the team demonstrates the fabrication of polymeric AFM probes covered by monolayer graphene that had been previously deposited on a prepatterned substrate. Furthermore, they show how graphene improves the functionality of the probes by making them conductive and more resistant to wear.The fabrication steps utilized in the process are very standard and highly compatible with current silicon fabrication technology, which allows its application in any clean room or microtechnology laboratory. The entire process is based on the multiple spincoating, exposure, and development of SU-8 photoresist on a prestructured mold.

The team also tested the conductivity of the graphene layer on the AMP probe. The results show a conductive behavior, proving the continuity of the graphene layer on the AFM probe.

Fuente: Nanowerk (2013), Improving AFM probe performance with a coat of graphene. Recuperado el 6 de mayo de 2013, de http://www.nanowerk.com/spotlight/spotid=30346.php

No hay comentarios:

Publicar un comentario